White Mesa Uranium Mill Tour

Before our community listening sessions and workshops in Utah this August, our consortium was able to tour the White Mesa Uranium Mill (owned and operated by Energy Fuels), currently the only functioning uranium mill in the country. We wanted to get a feel for both plant operations and their team’s perception of the main concerns in the communities around them.

Upon entering the mill we met the plant manager, Logan, in the conference room. We spent over an hour discussing community engagement, outreach, general mill operations, and the overall importance of energy and what they do at the site. Logan grew up in Blanding, Utah, the host city for the mill. His years spent abroad in the Philippines with less access to resources made him really appreciate electricity and lack of pollution even in a small rural town like Blanding. We talked about the importance of energy availability and how to balance messages to the community. Our team encouraged mill leadership to empower their employees to share about their work and experience at the mill with their families, friends, neighbors, and community at large. With 150 employees, the White Mesa mill is the largest employer in San Juan County, with almost half of the employees being native. Only about 5% are women. But all of those people can be good messengers especially for others like themselves.

With his chemistry background Logan gave us a pretty thorough run down of the chemical separation processes to extract the uranium from the ore or the waste they bring in. The raw uranium ore rock pilings are crushed and ground in water, to contain any dust. There were various tanks where various separation processes take place. When the uranium is finally extracted the water is evaporated, making yellow cake. They then further oxidize the yellow cake to turn it into uranium oxide which is the mill’s final uranium product.

The White Mesa Mill takes often acquires unique products that other industries are unsure of what to do with that have various levels of uranium “contamination.” Sometimes these packages would arrive with yellow stickies asking “Can you please take care of this for us?” With a variety of processing options available at the mill, they get to pursue novel problem solving and invent new separation methods to safely extract valuable uranium and other compounds from these samples. And in doing so, they are actually reducing contamination that other facilities cannot process. Logan’s unique view of this situation made us all rethink what we mean when we say the term “waste” and how much of the operations at the mill are actually making existing materials safer by removing and separating different components, harnessing the valuable ones, and leaving less waste behind at the end of the process.

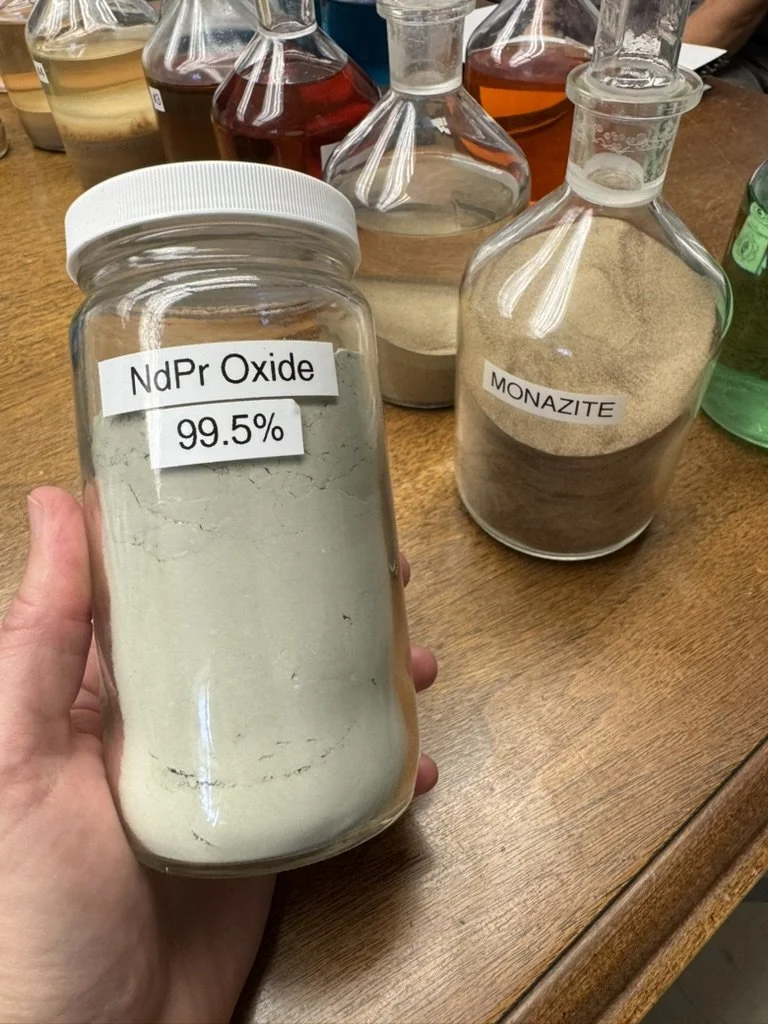

Some of these other compounds that are present in the uranium ore and in other samples the mill is asked to process are rare earth elements. Rare earths are vital for many industries particularly electronics like smart phones, computers, LEDs, TVs, and medical imaging equipment, but perhaps most importantly, they are necessary for strong magnets, like those used in electric cars. Stronger magnets need more of these materials, but lead to more efficient and higher-range EVs. Shortly after our visit, the company made this pretty exciting announcement regarding neodymium-praseodymium, which was one of the compounds in glass jars that we just learned about during our introduction to the facility.

The mill has large outdoor pools, called cells, where waste products get deposited. We were very curious to learn about these because there are lots of articles online where NGOs share community concerns of the ability to safely contain waste in these types of structures. Logan explained that each cell is lined with thick plastic with leak detection underneath. The newer cells have two layers of an even more resilient plastic and updated leak detection placed over a clay layer that self heals and protects the water table. Not only do they have monitoring for possible contamination in onsite wells, but Logan explained that the residential water table is a sealed off deeper aquifer that is completely isolated geographically from their operations. Just like in nuclear energy, we find that messaging about safety and barriers and protections that are in place reach certain audiences really well and help them feel better. But for others, this type of language may actually make them more nervous.

You can see some of the cells in the site photo behind Heather. She’s holding a chemical stripper solution that happens to be the same color as her uranium glass necklace.

Heather and Ryan checking out some Vanadium samples in the front lobby

As part of the disposal process, the cells are completely filled with sand and other byproducts, then dehumidified completely before being covered by a final layer of ground and vegetation. Because the mill is DOE land, this land will be monitored and in the care of the government for the foreseeable future. And there’s even some potential for future innovators to reclaim, reprocess, and recycle these materials further when technology advances, similar to how sometimes copper mining tailings have been processed again to extract even more copper.

Ladies day at the mill!

Some of the chemical processing tanks

Piles of uranium ore are right behind us

Char is one of about seven women who work at the mill. We found her in the lab processing samples.

The skill and expertise at this facility is a testament to how state of the art chemistry combined with a caring and conscientious staff can make extractive industries successful and low impact to our planet and human health. The White Mesa Mill is a hub of advanced technological knowledge for our nation and the local community. It is critical to our future that milling is done domestically and done well, with appropriate regulation, controls, and oversight, and that the community has trusted messengers to help them understand that this is the case.